How To Determine The Quality Of Makeup

Open access peer-reviewed chapter

Cosmetics' Quality Command

Submitted: March 16th, 2012 Reviewed: July 24th, 2012 Published: December 12th, 2012

DOI: 10.5772/51846

IntechOpen Downloads

12,580

Full Chapter Downloads on intechopen.com

*Address all correspondence to: veraisaac@fcfar.unesp.br

one. Introduction

The quality of a corrective product, in the same manner as to other kind of products, is initially defined past the manufacturer that chooses the features that a product should present. On the other mitt, the quality command of a product aims to verify if all of these defined features are in accordance with the standard definitions and if information technology will be maintained during the shelf life of the product (Shewhart, 1980).

The quality command of cosmetics is important to ensure the efficacy and safety of products and its raw-materials. Due to the rapid growth that cosmetic industries take showroom all over the world, efficient, low cost and rapid methods to assay cosmetics' quality control are a priority. Some current techniques used by the cosmetic industry can be applied to the evaluation of cosmetics' quality control in an efficient fashion, such every bit: rheology, sensory analysis and modest angle 10-ray scattering (SAXS).

Sensory analysis is a powerful tool, since there is no equipment able to measure the homo feelings. It applies experimental blueprint and statistical analysis to obtain data almost a product in relation to what people feel when employ or consume a product, in other words, information technology is used to indicate consumer acceptance of a particular product. It can be understood every bit the discipline that interprets, appraise and measures characteristics of a product, afterward stimulating people in relation to their vital senses, every bit vision, touch, scent and taste (Stone et al., 1992). It is widely used in food industry and recently, it has also been applied in the cosmetic industry (Almeida et al., 2008; Aust et al., 1987; Backe et al., 1999; Lee et al., 2005; Parente et al., 2005; Wortel et al., 2000).

The sensory analysis can be applied in the enquiry and development of a new corrective (Isaac et al., 2012a), in controlling the manufacturing process to evaluate raw-materials quality and, even, to brand possible the substitution of a raw-fabric of a production that is traditional in the market without changes in the product's features (Meilgaard et al., 1991; Muñoz et al., 1993).

The application of sensory assay could be related to the product control, referring to the storage, packaging and maintenance of sensory quality in relation to time and temperature (Muñoz et al., 1993), since these factors can modify a sensory aspect that the product present originally (Zague, 2008) and people who participates of the sensorial panel could realize the changes in the sensorial attributes. Another role of this important tool is to performance comparative tests between competing products.

Another tool that could exist practical to evaluate cosmetics' quality control is the rheology, which studies the flow and deformation of fluids. Information technology has been used in enquiry laboratories and industries as a tool for characterizing ingredients and products, and to predict the performance of products and consumer acceptance.

Rheology has been widely used because, by means of this tool, the researcher tin can determine physicochemical properties of a product. Constructing a rheogram, information technology is possible to check the menses curve, evaluate if there is a yield stress and a hysteresis area, which appears to be related to the release of drugs and actives. It is as well possible to construct a creep and recovery curve obtaining information well-nigh viscoelasticity of each system.

Specifically, in relation to the quality control of cosmetics, specifically, rheology can be applied to help in determining the stability of products by means of the credible viscosity measured periodically in a determined period exposing the samples to stress conditions (high and low temperatures, solar irradiation), and to monitor the menstruation characteristics during the shelf life or in the stability assay of a product.

The SAXS technique take beingness used for the analysis of cosmetics, in club to evaluate the presence of liquid crystalline structures, chosen liquid-crystals, which are known to increase the stability of formulations becoming, therefore, desirable in cosmetics (Makai et al., 2003).

Combining these iii tools, it is possible to test the quality of cosmetics with a rich range of information, and obtain a deep label of the organisation. The results contribute to determining product utilize, or even, they provide indication of what need to be done to develop a product with predetermined characteristics.

Advertisement

2. Sensory analysis

Sensory assay is defined by Piana et al. (2004) as the test of a product through the evaluation of the attributes perceptible by the 5 sense organs (organoleptic attributes), such as color, odor, sense of taste, touch, texture and noise, assuasive the establishment of the organoleptic profile of various products, including cosmetics.

The sensory analysis was first applied to the food manufacture, but the high advance in other areas, such equally the cosmetic and pharmaceutical industries, and the important information obtained with the sensory analysis, demanded this useful technique to describe what the consumers fell.

An important advantage of the use of sensory analysis in the quality control of a cosmetic product is that it yields a complex assay in relation to all sensorial attributes that a product could present, it means that, the volunteer who participates of the sensorial console is able to give information about the fragrance, the sensation, the appearance, the consistence, and other features that this person experience when utilize such production. The description of these characteristics by means of equipment would be an arduous work and would provide not sufficient or not valuable information when compared to the information provided by the human senses. Across that, the acquisition of this equipment could exist of loftier cost when compared to the sensory analyses' costs (Ross, 2009).

The association of data obtained from sensory analysis and instrumental analysis (especially physicochemical assay) provides great information and a more complete profile of the product (Ross, 2009).

Nowadays, there are companies specialized in perform sensory assay of cosmetic products, and thus, they could be contracted to perform this written report for corrective industries that don't have a sector trained to do it.

The sensorial performance of cosmetics is essential to the acceptance of consumers (Almeida et al., 2008; Fouéré et al., 2005; Lee et al., 2005; Proksch, 2005), thus, especial attention should be given to this discipline.

The sensorial features of a formulation are mainly related to the raw-materials and package (Dooley et al., 2009). The raw-materials influence directly in what the consumer feels when applies the cosmetic. The emollients, for case, are raw-materials of marked influence in the tactile sense (Parente et al., 2008; Gorcea and Laura, 2010). Other raw-materials are bachelor at the market and are commercialized to exist used in formulations as sensorial modifiers. The main representatives of this kind of product are the silicones and Polymethyl Methacrylate (Ozkan et al., 2012).

The package influences in the first impression of the consumer near a product, since the first sense used to cull a cosmetic in the marketplace is the vision. After, the smell is used too. The tact is not involved in the get-go buy attitude, but it will define if a consumer volition become a loyal consumer.

In this context, information technology is possible to verify that the sensorial features of a corrective are of great importance in the success of information technology in the market.

Thus, the sensorial assay could help a company to define the attributes that a production should or not present across the characteristics and intensity of these attributes.

Some other betoken is that these desired sensorial characteristics should be maintained during the cosmetic shelf life. To obtain that, the raw-materials used should be of practiced quality, the manufacture practices should be appropriate, the preservatives used demand to be efficient and the formulation should be stable.

In decision, the sensorial assay is an indispensable technique to assist the formulator to evaluate the quality of its new product, in relation to its sensorial characteristics and to its stability, testing if the production will keep the nice sensorial feelings that transmit to the consumer during the time of use. This tool is helpful to the research and development area of a company which aims to obtain skilful quality products of high acceptance past the consumers. The suitable awarding of sensory evaluation could avoid the outlay of a visitor with the launching of a production in the market that was rejected by the volunteers of the preliminary study.

Currently, the sensorial assay have gained more scientific rigor due to the need to offer to the consumers products that come across their expectations and due to the high competition betwixt the major industries of this sector.

To perform the sensorial assay with rigor and organisation, the laboratory destined to it must accept the following areas:

-

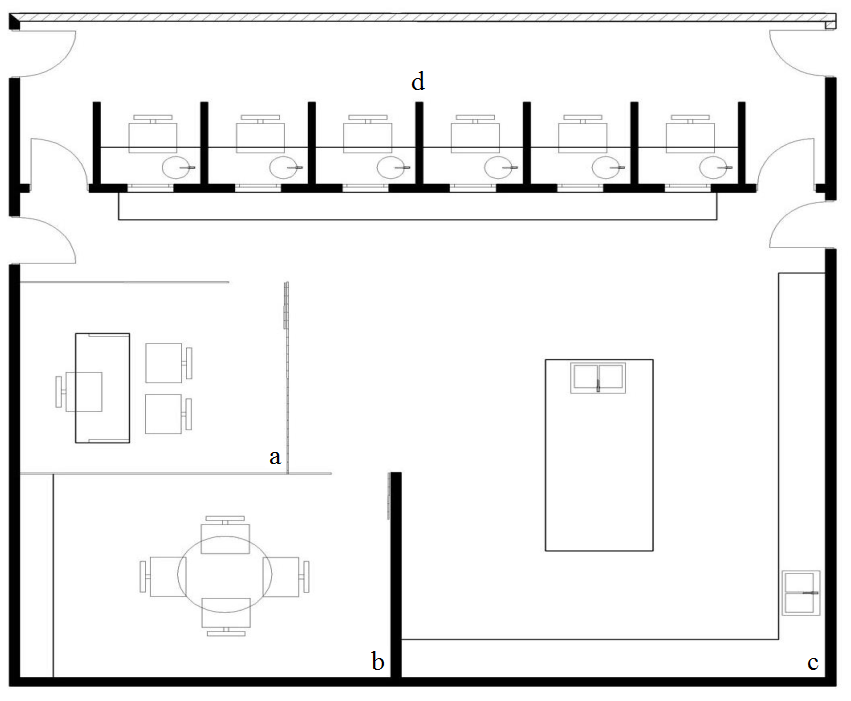

A room destined to the annotator who leads the team (Figure 1a)

-

A conference room (Figure 1b)

-

A room for the samples preparation (Figure 1c)

-

An surface area to the analyses with the volunteers (Figure 1d)

-

The laboratory should exist located in an easy access place.

Figure ane.

An example of layout of a sensorial analysis laboratory (

The area where will be performed the analyses should be divided in individual cabins (Figure 2) with a window, where the annotator must offer the samples to the volunteer, sink and faucet, to the volunteer use when necessary (Isaac et al., 2012).

Figure ii.

An example of layout of sensorial analysis cabine (

The cabins must be ventilated and odor gratis, to avoid interferences in the analyses. The temperature and humidity should be controled effectually 22 ºC and at 45% of humidity (Isaac et al., 2012).

It is recommended that the walls and furniture of the rooms are colored with neutral and low-cal colors to not disturb the attention of the volunteers and to not interfere in the attributes analyzed by the vision, such every bit color and appearance of the production.

The volunteers should not smoke, should be healthy, with ease of memorization and advice.

In the study, the volunteers judges could be an experienced judge or not, depending on the kind of evaluation and the answers that the professional squad needs to obtain. In the case of utilization of sensorial assay in the quality control of a cosmetic, usually the volunteers are regular users of the product in analysis, since they demand to be familiarized with the characteristics of the product and have sensibility to perceive slight modification on information technology. When the aim of the sensorial analysis is to evaluate the credence of a production that should be launched in the market, it is recommended that the volunteers are potencial users of this new product, orienting the formulator to make changes in the formulation and guiding the visitor to evaluate if the costs of the product launch are recommended or not.

There are four different methods to perform the sensorial analysis that are most used, they are: melancholia, discriminative, descriptive (Aust et al., 1987) and methods to evaluate the constructive of the product.

Independent of the method of sensory analysis suitable for each evaluation, the professional squad should use printed questionnaires to obtain the answers from each volunteer. The utilise of printed questionnaires avoids the contact between the professional and the volunteers preventing that the professional is biased in his responses, beyond that, it facilitates the data collection.

In the elaboration of these questionnaires the professional team should use suitable lexicons for each class of product, for case, the lexicons used to the evaluation of lip products are different from that used for corporal lotions (Dooley et al., 2009). Some researches had developed suitable lexicons for different classes of cosmetic products (Civille and Dus, 1991; Wortel and Wiechers, 2000; Dooley et al., 2009). The way as the volunteer is questioned is primal to obtain the information required from them. An inadequate formulary could invalidate a sensory evaluation. It is interesting besides, that a description of all descriptors attributed to the conception being provided to the volunteer, for example: "Thickness: Viscosity of the cream when picking upward from the container", "Ease of spreading: Ease of rubbing the sample over the skin", "Absorption: Ease of absorption of the product through the pare", "Residue: Amount of product left on the pare later application" (Parente et al., 2010).

The melancholia methods stand for the consumer opinion and evaluate how much consumers like or dislike a product. It is a quantitative method that is performed in order to know the consumers preferences (Aust et al., 1987). This technique could be practical in the evolution of new products and when it is necessary to replace a constituent of a formulation without loss of the product quality. It could be performed in ii different means: offering two different samples to the volunteer asking him about what sample he prefers between them or using a hedonic calibration for the volunteer attributes grades of intensity of its acceptation in relation to the sample.

The hedonic scale either can be presented to the console of evaluators in different manners, as shown in Effigy iii.

Figure three.

Examples of presentation of hedonic scale (

The affective methods provide quantitative data and permit more than one attribute in each sample existence evaluated at the aforementioned time.

The discriminative test is better represented by the Triangular exam. Information technology allows differentiating one between 3 different samples and is very useful in shelf life studies and in the quality command of cosmetics. The ideal is to perform this evaluation with twelve to forty volunteers, who will receive the three samples and should indicate the different one between them (Zenebon et al., 2008).

The descriptive tests provide a broad sensory description about the product that is being evaluated (Almeida et al., 2008), helping to predict the consumer acceptance and what consumers think about such product (Almeida et al., 2006; Aust et al., 1987).

The tests to evaluate the constructive of the products should be performed in true weather of apply and the volunteer may use but the product that is being assessed. These tests could be conduct by the evaluation of dermatologists, by the evaluation of volunteers, and fifty-fifty, by the measurement of ane parameter by un equipment, such equally the equipment that measures hydration, sebum and transepidermal water loss, to define if a product is actually effective. Based on these clinical evaluations, a company could create an efficacy claim to the product (Wortel and Wiechers, 2000).

The sensory analysis could be also applied when a cosmetic manufacture needs to supplant a raw-material of a commercialized product without changes in the performance of it. This replacement could exist originated by many factors, such as the reduction of costs, bug with the business firm who provides this raw-material bug with same raw material which causes irritation, comedogenicity or other bug that touch the consumer. In this field, the sensorial analysis helps the formulator, who proposes different raw materials as substitute, to evaluate if the consumer will notice the adaptation in the cosmetic product.

The statistical analysis is indispensable in the sensory studies. The sensory analysis data should be evaluated transforming them in scores which allows the application of statistical assay to summate the hateful and standard divergence of the results, and the decision if the difference betwixt the scores obtained is statistically significant. Graphics, tables and preference maps could be elaborated with the results obtained to facilitate the analysis of the data past the professional team.

The sensory analysis is particularly indispensable in the industries of fragrances and perfumes, and considering of that, high-resolution instrumental methods for evaluation of flavor and aroma take been adult and betwixt them are the breath assay via mass spectrometry (Dijksterhuis and Piggott, 2001; Ross, 2009). Instrumental measurements are idea to be objective, representing an independent fact or truth, however, the homo olfactory property sense is irreplaceable, being considered by Ross (2009) not necessarily valid because instrumental methods cannot account for the complexity of human perception.

Nevertheless, rheological studies accept been applied to objectify the sensations when cosmetic emulsions are applied to the skin (Brummer and Godersky, 1999).

Advertisement

3. Rheology

Rheology is a tool widely applied in the nutrient, petrochemical and pharmaceutical industries, but to the cosmetic manufacture it is incipient yet. Until now, the majority of cosmetic industries apply viscometers to guarantee that the viscosity of different batches of a product is maintained.

This affiliate was elaborated in order to show that many other rheological characteristics could be used to evaluate and to predict the stability of cosmetic products and could be applied to compare competing products in the market and to assay if a alter in the limerick will cause alterations that could be perceived by the consumer.

Kickoff, it is necessary to define the 3 parameters of nigh importance in rheology: shear stress, shear rate and viscosity. Shear stress tin can exist defined equally a force applied in an surface area. Shear rate is the ratio of the velocity of fabric to its distance from a stationary object (Naé, 1993). The shear rate can be calculated past the ratio between the velocity and the layer or film thickness. In a lipstick application, for case, with a velocity estimated in 5 cm/s and a layer thickness of 0.ane mm, the ratio (shear rate) is 5.102 south-one. Finally, the viscosity can be defined equally the resistance to flow. Thus, a viscous production presents smaller menses than others.

Last, rheology is the study of deformation and flow of materials nether external forces. Some equations and the units of these parameters are (Naé, 1993):

Where:

σ = shear stress (Pa = kg.m-1.s-2)

F = strength (N or kg.m.s-2)

A = area (10002)

The viscosity tin can exist defined as the ratio between shear stress and shear rate:

Where:

= viscosity

= shear stress (Pa)

Since the unit of shear stress is Pa and the unit of deformation is south-1, the unit of viscosity is Pa.s. These parameters are involved in scientific measurements of rotational assays.

Using controlled shear rate and measuring shear stress is possible to behave out rotational assays, and make up one's mind menstruum curves and describe the models: Newtonian or not-Newtonian and, amongst the terminal one, plastic, pseudoplastic, dilatant, tixotropic and reopetic fluids. Newtonian fluids are materials that present constant viscosity, independent of time and temperature. These materials present catamenia curves with proportionality between shear stress and shear charge per unit. The Figure 4 represents the flow curve of a Newtonian cloth.

Figure 4.

Flow bend of a Newtonian fabric.

In the case of non-Newtonians materials, this proportionality between shear stress and shear rate does not happen.

If in the offset of the flow curve in that location is an increasing in the shear stress but the shear rate is equal to naught, and later on to information technology is verified a Newtonian menses, this fabric is called plastic. This initial shear stress with shear rate equal to zero is called yield value and it represents the shear stress necessary for the material flow. The Figure 5 represents a plastic material. The yield value is related to the free energy required to deform the cloth sufficiently and so that they tin can flow. The value of the yield stress tin exist determined past measuring the deformation of the cloth equally a part of the applied stress (Abdel-Rahem et al., 2005).

For non-Newtonian materials time-dependents, if the viscosity decreases with the shear rate, the material is chosen pseudoplastic and if the viscosity increases, the textile is called dilatant. On the other mitt, if the material is time-independent, it will exist chosen tixotropic if the viscosity decreases with the shear charge per unit or reopetic if the viscosity increases with the shear rate (Naé, 1993). When the ascending and the descending curves of the flow curve exercise not overlap it shows thixotropy which is a desirable feature for cosmetics and semisolid drug carriers for topical awarding (Lippacher et al., 2004). The Figures 6, seven, 8 and 9 represent the menstruum curves of non-Newtonian materials (Naé, 1993).

Figure 5.

Flow curve of a plastic material.

Figure 6.

Flow curve of a pseudoplastic material.

For screening purposes and in the initial phases of the formulation development, the rheological tests proved to exist very useful for the study of stability.

In a stability analysis to make up one's mind the shelf life of a recently developed product, the conception should be exposed to stress conditions, such every bit storage at -five ºC, 45 ºC, and cycles of -5 ºC during 24 hours followed past exposure to 45 ºC during more than 24 hours. This procedure is washed in order to induce the appearance of instability signals in the formulations, where tin exist cited the darkening of the formulation, the precipitation of a constituent, the phase separation in the case of emulsions, and other signals. These stressing conditions are kept for a period around two or three months.

Figure seven.

Flow curve of a dilatant textile.

Figure 8.

Flow curve of a thixotropic material.

Figure 9.

Catamenia curve of a reopetic cloth.

It is usually measured the viscosity of the stressed formulations periodically during the stability assay. It could be done by means of a viscometer or by using a rheometer.

With a viscometer, it is possible to behave out rotational assays or measurements by steady-state flow. On the other paw, the rheometer allows the development of oscillatory assays or dynamic measurements (Biradar, 2009).

When using an oscillatory rheometer it is necessary to bear out a menstruum curve analysis and determine the credible viscosity of the formulation in a defined shear rate. Information technology is recommended to apply the higher shear rate in the dominant bend of the period bend, since in this point the sample is in a suitable condition, it means that the formulation is not starting to flow and is not excessively sheared (Effigy 10).

Figure 10.

Case of a flow bend indicating the status to the measurement of apparent viscosity.

In some papers, the catamenia curves accept been plotted every bit viscosity as a function of shear stress instead of the traditional approach of plotting information technology versus shear charge per unit because has been previously found that such curves are more discriminating and requite better results for evaluation (Roberts, 2001; Samavati, 2011).

After obtaining, periodically, the minimum apparent viscosity of the samples exposed to stress atmospheric condition during a period, they should exist compared with the initial value, and also compared the viscosity values of the control with the samples exposed to stress conditions, which allows the verification of the increase, decrease or maintenance of this attribute of the formulations.

Further exploiting the aforementioned assay, it is possible to calculate the hysteresis area of the formulation in each flow curve performed during the stability assay. The hysteresis loop areas can be obtained through a three-step experiment: upward curve, plateau, down (Benchabane and Bekkour, 2008) and represents a style to measure out, indirectly, the spreadability of the conception, then information technology is possible to ascertain if the conception losses or gains easiness on spreadability during the shelf life. How much bigger is the hysteresis surface area, higher is the spreadability.

Effigy 11.

Flow bend with hysteresis area.

Using the catamenia curve is possible to compare two samples in relation to its hysteresis area and viscosity. A simple way to verify what formulation have a college viscosity is past uncomplicated ascertainment of the rheogram, since the curve that forms a bigger inclination in relation to the

Effigy 12.

Comparison between menstruum curves of different samples (a thixotropic and a plastic fluid).

Beyond the different sensorial features caused by the differences in viscosity is known that the viscosity of emulsioned systems is ane of the factors that retards or avoids the phase separation processes. The coalescence of dispersed stage can exist due to the emulsifier agent and tin can be related to an instability because of low viscosity of dispersed stage (Corrêa & Isaac, 2012). This depression viscosity can occur considering of high shear stress (Samavati et al., 2011).

In general, for emulsioned systems, the continuos phase is shear thinning, which means that its viscosity decreases with the increasing on shear rate and viscoelastic, which means that it has viscous and elastic components (Tadros, 2004).

An example of the verification of differences in viscosity and thixotropy betwixt two samples is shown on Figure 13.

Effigy thirteen.

Comparison between flow curves of different samples.

Sample 1 is less sticky but more than thixotropic than formulation 2. This simple verification gives to the annotator broad information, depending on what he needs.

Lescanne et al. (2004) studied organogels and aging properties of them. Organogels can exist obtained by precipitation processes. These authors verified that, when aggregates are formed by the cooling charge per unit, can be observed a elastic behavior, still, these aggregates tin can be aligned in the direction of the period without lost the structure and when the menstruation is stopped, the aggregates are rapidly rearranged and information technology inducing an thixotropic behavior. When the hot solution is introduced between the flat and the conical plates of the rheometer jail cell information technology is cooled to 5 ºC with a cooling rate of 20ºC/min, during the commencement hour of the gel life, it was measured the elastic properties of a gel equally a function of time but afterward the cooling. Five minutes after its formation, the gel was submitted to a periodic stress (0.5 Pa) at a constant frequency (

The menstruation curve is a rotational assay, merely using a rheometer it is possible to perform oscillatory assays too. Among the oscillatory assays are stress sweep and the frequency sweep assays.

The elastic (storage) modulus Thou' and the viscid (loss) modulus G'' are adamant as a function of frequency or stress. The elastic modulus is a mensurate of energy stored and recovered per cycle of deformation and represents the solid-like component of a viscoelastic material. If a sample is elastic or highly structured then the rubberband modulus will exist high. The mucilaginous modulus is a measure of the free energy lost per bicycle and represents the liquid-similar component. If a sample is pasty the viscous modulus will exist high.

In the stress sweep analyses, the construction of the sample is progressively destroyed past applying oscillations with an increasing stress aamplitude at a fixed frequency (Callens et al., 2003). The linear viscoelasticity region occurs over that region of strain where the complex modulus is independent of the strain (Hemar, 2000). The linear viscoelastic region is determined past the maximum stress which can be applied without affecting G' and K''. Furthermore, the relative magnitude of the moduli is a qualitative indication for the construction in the sample. Two different situations can occur: G' > M'' for a network consisting of secondary bonds and M'≤ G'' for a physically entangled polymer solution (Callens et al., 2003).

Frequency sweep tests are performed in the linear viscoelastic region of each sample, keeping the structure of the system intact during the measurement. By performing such small stress amplitude oscillations at a whole range of frequencies, the blazon of network structure can be revealed. The master divergence betwixt a network of secondary bonds and i of physical entanglements is located in the depression frequency range: in an entangled network the polymers can uncrease if the available time is long enough (depression frequency). In a network with secondary bonds the bonds are fixed irrespective of the time scale. This results for an entangled solution in a limiting gradient of 2 for One thousand' and ane for Thousand'' at depression frequency in a log-log plot of moduli versus frequency, while at intermediate frequency a plateau develops. For a network of secondary bonds an almost constant value of G' and G'' is observed over the whole frequency range, with the value of Grand' exceeding that of Thou''(Callens et al., 2003; Madsen et al., 1998).

The stress sweep is important to evaluate the linear viscoelastic region of a sample that is a range of shear stress in which the formulation does not endure profound alterations on information technology construction, being not disrupted. When a shear stress of the linear viscoelastic region is practical in an oscillatory assay, only the intermolecular and interparticle forces are being evaluated (Martin, 1993). To decide the linear viscoelastic region, the oscillating stress sweeps are carried out for the most extreme values. These measurements are used to make up one's mind where the reological backdrop are independent of the applied stress and the identify the disquisitional rheological properties (Tuarez, 2011).

Knowing the values of shear stress that do not cause the disrupt in the conception by means of the stress sweep, the analyst could perform a frequency sweep of the formulation. The frequency sweep is carried out in a constant shear stress institute in the linear viscoelastic region. With this assay it is possible to evaluate the elastic or storage modulus (Chiliad') and the viscous or loss modulus (One thousand''). The corrective excipients most used, emulsions and gels, are often viscoelastic samples. The viscoelastic samples when evaluated by ways of the frequency sweep present One thousand' and G'' values. When the G' value is higher than Yard'' it is an indicative that the formulation is more elastic than viscous. Information technology is a characteristic of gels.

Emulsions which exhibits Thousand' values higher than G'' (Effigy 14) are described as more than stable than formulations with G'' values college than Thou' (Figure 15), since they tends to recovery its initial construction faster and more efficiently than the others, and are less susceptible to the gravitational forces which retards or avoids the coalescence process and the phase separation of emulsions (Alam and Aramaki, 2009). So, the G' values higher than G'' in emulsions is a desirable feature, beingness an indicative of stability of the cosmetic system.

Figure 14.

A frequency sweep example (Thou'>Grand'').

Figure 15.

A frequency sweep example (G''>Thousand').

Some other assay that could be conducted using an oscillatory rheometer is the pitter-patter and recovery assay. It is washed by submitting the samples to a constant shear stress during a catamenia, and after, removing this shear stress and monitoring the formulation in relation to the deformation (measured by the compliance - J) during the same period. The compliance parameter is the resulting strain divided by the applied stress (Koop, 2009; Toro-Vazquez et al., 2010). If the compliance parameter is the relationship between strain and the applied stress, the strain is dimensionless and stress is measured in Pa, then, the compliance can be measured in ane/Pa.

In the case showed on the Figure 16 the samples were submitted to a shear stress during 300 seconds, and afterwards removing this shear stress it was monitored during more than 300 seconds.

Analyzing the result obtained in the beginning 300 seconds is verified that sample 1 exhibited lower compliance values than sample 2, which represents a higher difficult on being deformed than sample 1. The difficult on being deformed is always linked to higher viscosity values.

In the second part of the assay, where the shear stress imposed to the sample is removed, represented in the graphic by the fourth dimension 301 to 600 seconds, is verified the viscoelastic properties of the samples. Formulations that are able to recovery its initial structure or role of information technology exhibit a gradually decrease in the compliance values. On Figure 17 there is an instance of a formulation that is not a viscoelastic sample, it means that it do not exhibits storage modulus, and is not able to recovery its construction when the shear stress is ceased.

Figure xvi.

A creep and recovery example of viscoelastic samples.

Figure 17.

A creep and recovery example of a non-viscoelastic sample.

In improver, the rheology can be used to evaluate the stability over the time by dynamic and oscillatory rheological measurements (Pénzes et al., 2004; Vasiljevic et al., 2006) and the release of active principles. According to Martinez et al. (2007), the transdermal assimilation of topically administered drugs depends on the rate of release and the permeability of them into the peel and also of the viscosity of the formulation (Martinez et al., 2007).

Thus, it is possible to say that different categories of products should present peculiar rheological properties inherent to its application (Gregolin et al., 2010).

In this manner, the rheology can influence the diffusion coefficient, altering the release and permeation of cosmetics active substances (Welin-Berger et al., 2001; A-sadutjarit et al., 2005; Vasiljevic et al., 2006). Some authors have related the influence of rheological characteristics on the release profiles and consequently in the permeation of active substances in the skin; thus, the addition of thickening agents or attainment of a weak-gel because of physical entanglement of polymer chains must be considered in the choice of cosmetics bases (Spiclin, et al., 2003). Thus, rheology can aid in the assay of release and permeation in the peel. Some studies take been published nigh information technology.

So, in a brusque style, the rheology is a valuable tool that helps in the quality control of cosmetics, being used in the stability tests, in the comparison betwixt competing samples, in the comparison between an original product and a product with an amending in a elective, and in the evolution of new products, aiming to develop cosmetic with rheological characteristics which betoken stability.

Advertisement

four. Minor Angle X-ray Handful (SAXS)

The use of this technique in determining the quality control of a cosmetic is closely related to the stability of the product, which could be improved with the presence of liquid crystals.

Liquid crystals are described equally a state of thing between solids and liquids, it ways that, they are fluid like liquids just are organized like solids, beingness chosen mesophases (Marsh, 1973; Kelker and Hatz, 1980; Müller-Goymann, 2004). These organization contributes to the highly stability of systems.

The germination of liquid crystals in emulsions could be induced by some components present in this system, such equally surfactants (Müller-Goymann, 2004). So, what happens is that it is possible to find a peculiar organization that is not a simple emulsion and non a genuine liquid crystal, merely an emulsioned organization that contains liquid crystals, usually lamellar structures, that are formed around of the inner stage of the emulsion (Oka et al., 2008), making difficult the coalescence, flocculation and the separation of the oily and h2o phases, what makes the system formed more than stable than a simple emulsion (Figures eighteen and 19). Flocculation is divers as the germination of aggregates of droplets of an emulsion under the influence of interparticle colloidal forces which are net attractive (Dickinson, 1992) and the germination of lamellar structures avoid or prevent the occurrence of this phenomenon. The formation of lamellar structures is essential to obtain emulsified oil/water systems finely dispersed, with counterbalanced hydrophilic-lipophilic backdrop, resulting in minimal interfacial tension between aqueous and oily phases, thus contributing to the stability of the system (Engels et al., 1995). Previous studies have also shown that it is possible to brand correlation between SAXS and rheological analysis, since were verified that the thicker the interlamellar water layers, the higher the viscosity of the cream (Eccleston et al., 2000). Thus, liquid crystals could exist responsible by the emulsion stabilization and by the increasing in the viscosity (Klein, 2002), being the presence of this structures desirable in cosmetic emulsions which could be an indicative of quality of them.

Figure eighteen.

Scheme of a corrective emulsion containing liquid crystals.

Figure 19.

Schemes of the microscopic visualization of lamellar gel networks surrounding emulsion droplets proposed by Klein (2002).

This kind of construction is more commonly institute in cosmetics due to the high diversity of components used in it in order to obtain a moisturizer, emollient, humectant, good sensory and, above all, stable cosmetic. In other pharmaceutical forms, usually are used a less diversified composition, which gives a system easier to understand, described equally emulsion or liquid crystal, or even, a gel, a pause, etc. The quantity of these lamellar structures, found in cosmetic emulsions, probably is dependent of iii principal factors: the raw-materials, the amount of it used and the process of preparation, where should be cited, the temperature and the speed of agitation.

In cosmetics, other kinds of systems could be used, such as genuine liquid crystals aiming to explore its characteristics of controlled commitment systems.

In that location are different kinds of liquid crystals and unlike classifications, only this affiliate has not the function of draw them, since information technology have been done by many authors (Bechtold, 2005; Formariz et al., 2005; Atkins and Jones, 2006), the aim was to demonstrate the importance of these structures in the maintenance of the cosmetics' quality. Nevertheless, co-ordinate to the literature data (Klein, 2002) and to our experience in this subject, it is possible to say that the lamellar arrangement is the most unremarkably found in corrective emulsions.

An initial assay of the presence of liquid crystals in a cosmetic emulsion could be done using a polarized calorie-free microscope, but it should be confirmed and meliorate analyzed by means of Small Bending X-Ray Scattering. When a microscope slide containing a sample of the system is studied and it presents structures that reverberate the incident calorie-free, it is an show of the presence of liquid crystals (Figure 20). So, they should exist submitted to SAXS analysis to confirm this expectation (Savic et al., 2011).

Figure 20.

Photomicrographs of liquid-crystal nowadays in emulsions evaluated by polarized light microscope.

The SAXS method requires a synchrotron light source that is formed by means of a particle accelerator, and using a monochromatic beam, that is used to irradiate the sample. After that, the scattering of the rays in small bending should be analyzed (Glatter and Kratky, 1982; Urban, 2004; Koch, 2010). Liquid crystals tin can be analyzed by SAXS since they are able to disperse the Ten-rays focused on it. In the SAXS line is used an X-rays detector and an multichannel analyzer to capture the intense of the SAXS measures (

Analyzing the data obtained (Effigy 19), the

Effigy 21.

Hypothetical SAXS curve.

In the case of the hypothetical curve showed in Figure 19,

Beyond the advantages already mentioned, in a enquiry conducted by Moaddel and Friberg (1995), the authors showed that the presence of lamellar liquid crystals in an emulsion avoids the water evaporation rate in this system, thus contributing in another way to the stability and maintenance of the cosmetic quality.

According to the advantages obtained with the presence of liquid crystals, these mesophases can exist of keen importance to the Cosmetic Industry in the evolution of very stable cosmetics and, the SAXS technique, an efficient tool to confirm the presence of these desirable structures that helps in the maintenance of cosmetics' quality control.

Camerel et al. (2003) pointed the importance in correlate the microstructure of a colloidal pause with its rheological behavior to define its meliorate employ in industry and in life, across that, according to these authors in that location are few reports correlating these analyses.

Our research group has invested in researches to appraise the stability of cosmetics (Isaac et al., 2008); evaluating of the influence of the addition of thickening agents in creams using rheological measurements (Isaac et al., 2012a); evaluating the thickeners' influence on the rheological properties of a cosmetic (Isaac et al., 2012b,c); proposing alternative methods to assay the efficacy and prophylactic of them (Chiari et al., 2012a; Chiari et al., 2012b) and using of the sensory analysis in the cosmetics development (Isaac et al., 2012a) which, in dissimilar points of view of what was demonstrated in this chapter, likewise influence in the product quality.

Advertisement

v. Conclusion

This chapter aimed to show the facility that some elementary or avant-garde techniques already used, sometimes to other finalities, could offer to the quality control of corrective products. The sensory analysis, rheology and SAXS technique have earned attention due to the important contribution that they can offer to the cosmetic area.

References

- 1.

Abdel-Rahem, R., Gradzielski, M., & Hoffmann, H. (2005). A novel viscoelastic system from a cationic surfactant and a hydrophobic counterion. Journal of Colloid and Interface Scientific discipline, 288, 570–582. - ii.

Alam, M.M., & Aramaki, M. (2009). Glycerol effects on the formation and rheology of hexagonal stage and related gel emulsion, J. Colloid Interface Sci., 336, 820-826. - 3.

Alexandridis, P., Olsson, U., & Lindman, B. (1998). A record nine dissimilar phases (four cubic, two hexagonal, and one lamellar lyotropic liquid crystalline and two micellar solutions) in a ternary isothermal system of an amphiphilic block copolymer and selective solvents (h2o and oil). Langmuir, xiv, 2627-2638. - 4.

Almeida, I.F., Gaio, A.R., & Bahia, Thousand.F. (2006). Estimation of hedonic responses from descriptive skin sensory data by chi squared minimization. J. Sens. Stud., 21(one), 2-19. - 5.

Almeida, I.F., Gaio, A.R., & Bahia, Thousand.F. (2008). Hedonic and descriptive skinfeel analysis of ii oleogels: comparison with other topical formulations. J. Sens. Stud., 23(i), 92-113. - half-dozen.

A-Sadutjarit, R., Sirivat, A., & Vayumhasuwan, P. (2005). Viscoelastic properties of carbopol 940 gels and their relationships to piroxicam diffusion coefficients in gel bases. Pharmaceutical Research, 22(12), 2134-2140. - 7.

Atkins, P., & Jones, L. (2006). Princípios de química: questionando a vida moderna e o meio ambiente. Porto Alegre: Bookmam. 3ed., p. 293-295 and 300-302. - 8.

Aust, L.B., Oddo, P., Wild, J.E., Mills, O.H., & Deupree, J.Due south. (1987). The descriptive analysis of skin care products past a trained panel of judges. J. Soc. Cosmet. Chem., 38, 443-448. - ix.

Backe, I., Meges, S., Lauze, C., Macleod, P., & Dupuy, P. (1999). Sensory analysis of four medical spa spring waters containing diverse mineral concentrations. Int. J. Dermatol., 38(ten), 784-786. - 10.

Barkat, Due south., Thomas-Danguin, T., Bensafi, G., Rouby, C., & Sicard, K. (2003). Odor and color of cosmetic products: correlations betwixt subject sentence and autonomous nervous arrangement response. International Journal of Cosmetic Science, 25, 273-283. - xi.

Bechtold, I. H. (2005). Liquid crystals: A complex system of simple awarding. Rev. Bras. Ensino Física, 27(3), 333-342. - 12.

Benchabane, A., & Bekkour, Chiliad. (2008). Rheological properties of carboxymethyl cellulose (CMC) solutions. Colloid Polymer Science, 286, 1173-1180. - xiii.

Biradar, South.V., Dhumal, R.Southward., & Paradkar, A. (2009). Rheological investigation of cocky-emulsification process. Journal of Pharmacy and Pharmaceutical Science, 12(1), 17-31. - 14.

Brummer, R., & Godersky, S. (1999). Rheological studies to objectify sensations occurring when cosmetic emulsions are applied to the skin. Colloids and Surfaces A: Physicochemical and Engineering science Aspects, 152, 89-94. - 15.

Callens, C., Ceulemans, J., Ludwig, A., Foreman, P., & Remon, J.P. (2003). Rheological report on mucoadhesivity of some nasal pulverization formulations. European Journal of Pharmaceutics and Biopharmaceutics, 55, 323-328. - 16.

Camerel, F., Gabriel, J.C.P., Batail, P., Panine, P., & Davidson, P. (2003). Combined SAXS – Rheological studies of liquid-cristalline colloidal dispersions of mineral particles. Langmuir, 19, 10028-10035. - 17.

Chiari, B.Thousand., Magnani, C., Salgado, H.R.Due north., Côrrea, K.A., & Isaac, Five.L.B. (2012a). Estudo da segurança de cosméticos: presente e futuro. Revista Brasileira de Ciências Farmacêuticas Básica e Aplicada, 33(2). - 18.

Chiari, B.G., Martini, P.C., Moraes, J.D.D., Andréo, R., Corrêa, M.A., Cicarelli, R.M.B., & Isaac, V.L.B. (2012b). Use of HepG2 cells to assay the prophylactic of cosmetic active substances. International Journal of Research in Cosmetic Scientific discipline, 2(2), 8-fourteen. - 19.

Civille, C.V., & Dus, C.A. (1991). Evaluating tactile properties of skincare products: A descriptive analysis technique. Cosmet. Toilet., 106, 83–88. - 20.

Corrêa, M.A., & Isaac, V.50.B. (2012). Emulsões. In: CORRÊA, Yard.A. Cosmetologia: ciência e técnica. São Paulo: Medfarma, p. 337-381. - 21.

Craievich, A. F. (2002). Synchrotron SAXS studies of nanostructured materials and colloidal solutions. Materials Research Rev., five(1), 1-11. - 22.

Dickinson, E. (1992). Structure and composition of adsorbed protein layers and the relationship to emulsion stability. J. Chem. Soc. Faraday Trans., 88(20), 2973-2983. - 23.

Dijksterhuis, Grand. B., & Piggott, J. R. (2001). Dynamic methods of sensory analysis. Trends in Food Science and Technology, 11, 284-290. - 24.

Dooley, Fifty.K., Adhikari, K., & Chambers IV, E. (2009). A full general lexicon for sensory analysis of texture and appearance of lip products. J. Sens. Stud., 24(4), 581-600. - 25.

Eccleston, 1000.M., Behan-Martin, 1000.Chiliad., Jones, K.R., & Towns-Andrews, E. (2000). Synchrotron 10-ray investigations into the lamellar gel phase formed in pharmaceutical creams prepared with cetrimide and fatty alcohols. International Journal of Pharmaceutics, 203, 127–139. - 26.

Engels, T., Förster, T., & Von Rybinski, W. (1995). The influence of coemulsifier blazon on the stability of oil-in-water emulsions. Colloids Surfaces A: Physicochemical and Technology Aspects, 99, 141-149. - 27.

Formariz, T.P., Urban, Chiliad.C.C., Da Silva Júnior, A.A., Gremião, Yard.P.D., & De Oliveira, A.1000. (2005). Microemulsões e fases líquidas cristalinas como sistemas de liberação de fármacos. Revista Brasileira de Ciências Farmacêuticas, 41(3), 301-313. - 28.

Fouéré, S., Adjadj, L., & Pawin, H. (2005). How patients experience psoriasis: results from a European survey. J. Eur. Acad. Dermatol. Venereol., 19(iii), 2-6. - 29.

Glatter, O., & Kratky, O. (1982). Pocket-sized-Angle X-ray Handful, Academic Printing, New York. - 30.

Gorcea, 1000., & Laura, D. (2012). Evaluating the physiochemical backdrop of emollient esters for cosmetic utilise. Cosmetics and Toiletries, 125(12), 26-33. - 31.

Gregolin, Thou.T., Chiari, B.M., Ribeiro, H.M., & Isaac, V.L.B. (2010). Rheological Characterization of hydrophilic gels. Journal of Dispersion Science and Technology, 31, 820-825. - 32.

Hemar, Y., & Horne, D.S. (2000). Dynamic rheological properties of highly concentrated protein-stabilized emulsions. Langmuir, sixteen(7), 3050-3057. - 33.

Isaac, Five.L.B., Cefali, 50.C., Chiari, B.G., Almeida, Chiliad.Yard.J., Ribeiro, H. One thousand., & Corrêa, G.A. (2012c) Issue of various thickening agents on the rheological properties of O/W emulsions containing non-ionic emulsifier. Periodical of Dispersion Science and Applied science. Available at: http://world wide web.tandfonline.com/doi/full/10.1080/01932691.2012.695952 - 34.

Isaac, 5.L.B., Cefali, L.C., Chiari, B.G., Oliveira, C.C.L.G., Salgado, H.R.Northward., & Corrêa, M.A. (2008). Protocolo para ensaios físico-químicos de estabilidade de fitocosméticos. Rev. Ciênc. Farm. Básica Apl., 29(1), 81-96. - 35.

Isaac, V., Chiari, B.G., Magnani, C., & Corrêa, Thousand.A. (2012a). Análise sensorial como ferramenta no desenvolvimento de cosméticos. Revista de Ciências Farmacêuticas Básica east Aplicada, 33 (in press). - 36.

Isaac, V.L.B., Moraes, J.D.D., Chiari, B.Yard., Guglielmi, D.A.S., Cefali, 50.C., Rissi, N.C., & Corrêa, Thou.A. (2012b). Determination of the existent influence of the addition of four thickening agents in creams using rheological measurements. Bachelor at: http://www.tandfonline.com/doi/full/x.1080/01932691.2012.683759 - 37.

Kelker, H., & Hatz, R. (1980). Handbook of Liquid Crystals, Verlag Chemie, Weinheim, Federal republic of germany. - 38.

Klein, 1000. (2002) Liquid crystals and emulsions: a wonderful matrimony. Affiliate 26, p. 265-269. In: Skin Barrier: Chemistry of Delivery Systems. Available at: http://www.alluredbooks.com/sample_pages/skin_barr_chem_skin_deli_syst_ch26.pdf. Acessed on july, 2012. - 39.

Koch, M.H.J. (2010). SAXS Instrumentation for Synchrotron Radiation then and now. Xiv International Conference on Small-Bending Scattering (SAS09). Journal of Physics: Conference Serial 247. - 40.

Koop, H.S., Praes, C.Eastward.O., Reicher, F., Petkowicz, C.L.O., & Silveira, J.L.M. (2009). Rheological beliefs of gel of xanthan with galactomannan: effect of hydroalcoholic-ascorbic acrid. Materials Scientific discipline and Engineering science C, 29, 559-63. - 41.

Lee, I-S., Yang, H-M., Kim, J-W., Maeng, Y-J., Lee, C-Westward., Kang, Y-South., Rang, Thou-J., & Kim H-Y. (2005). Terminology development and panel training for sensory evaluation of peel care products including aqua foam. J. Sens. Stud., 20(5), 421-433. - 42.

Lescanne, Yard., Grondin, P., D'Aléo, A., Fages, F., Pozzo, J.Fifty., Moundain Monval, O., Reinheimer, P., & Colin, A. (2004). Thixotropic organogels based on a uncomplicated N-hydroxyalkyl amide: rheological and aging properties. Langmuir, 20(8), 3032-3041. - 43.

Lippacher, A., Müller, R.H., & Mäder, Yard. (2004). Liquid and semisolid SLNe dispersions for topical application: rheological characterization. European Journal of Pharmaceutics and Biopharmaceutics, 58, 561–567. - 44.

Madsen, F., Eberth, K., & Smart, J.D. (1998). A rheological assessment of the nature of interactions betwixt mucoadhesive polymers and a homogenized mucus gel. Biomaterials, 19, 1083-1092. - 45.

Makai, M., Csányi, Eastward., Németh, Z.S., Pálinkás, J., & Erós, I. (2003). Structure and drug release of lamellar liquid crystals containing glycerol. Int. J. Pharm., 256, 95–107. - 46.

Marsh, H. (1973). Carbonization and liquid-crystal (mesophase) development: Part 1. The significance of the mesophase during carbonization of coking coals. Fuel, 52, 205-212. - 47.

Martin, A. (1993). Physical Pharmacy, fourth ed., Lea & Febiger, Philadelphia. - 48.

Martinez, Chiliad.A.R., Gallardo, J.L.Five., Benavides, M.M., López-Duran, J.D.G., & Lara, V.G. (2007). Rheological behavior of gels and meloxicam release. International Journal of Pharmaceutics, 333, 17-23. - 49.

Meilgaard, K., Civille, Chiliad.V., & Carr, B.T. (1991). Consumer test and in-business firm panel acceptance tests. In: Meilgaard, One thousand., Civille, G.V., Carr, B.T. Sensory evaluation techniques. Florida: CRC Printing, p. 142-7, 281. - 50.

Moaddel, T., & Friberg SE. (1995). Stage equilibria and evaporation rates in a four component emulsion. J. Disp. Sci. Technol., 16, 69-97. - 51.

Molina, C., Dahmouche, K., Hammer, P., Bermudez, V.Z., Carlos, L.D., Ferrari, M., Montagna, Thou., Gonçalves, R.R., De Oliveira, L.F.C., Edwards, H.One thousand.One thousand., Messaddeq, Y., & Ribeiro, Southward.J.L. (2006). Structure and Properties of Ti4+-Ureasil Organic-Inorganic Hybrids, J. Braz. Chem. Soc., 17(3), 443-452. - 52.

Müller-Goymann, C.C. (2004). Physicochemical characterization of colloidal drug delivery systems such equally contrary micelles, vesicles, liquid crystals and nanoparticles for topical administration. European Journal of Pharmaceutics and Biopharmaceutics 58, 343–356. - 53.

Muñoz, A.Yard., Civille, Grand.V., & Carr, B.T. (1993). Sensory evaluation in quality control. New York: Van Nostrand Reinhold, p. 240. - 54.

Naé, H.North. (1993). Introduction to rheology. In: Laba, D. Rheological propertie of cosmetics and toiletries. New York: Marcel Dekker, 426 p. - 55.

Oka, T., Miyahara, R., Teshigawara, T., & Watanabe, Thousand. (2008). Development of novel corrective base using sterol surfactante. I. Grooming of novel emulsified particles with sterol surfactant. Journal of Oleo Science, 57(10), 567-575. - 56.

Olshan, A.A., Kohut, B.E., Vincent, J.W., Borden, L.C., Delgado, North., Qaqish, J., Sharma, N.C., & Mcguire, J.A. (2000). Clinical effectiveness of essential oil-containing dentifrices in controlling oral malodor. American Journal of Dentistry, 13, 18C-22C. - 57.

Ozkan, Southward., Gillece, T.W., Senak, L., & Moore, D.J. (2012). Characterization of yield stress and slip behaviour of skin/pilus care gels using steady flow and LAOS measurements and their correlation with sensorial attributes. International Journal of Corrective Science, 34, 193–201. - 58.

Parente, M.East., Ares, G., & Manzoni, A.Five. (2010). Awarding of 2 consumer profiling techniques to cosmetic emulsions. Journal of Sensory Studies, 25, 685-705. - 59.

Parente, 1000.Due east., Gámbaro, A., & Ares, G. (2008). Sensory characterization of emollients. Journal of Sensory Studies ii, 149–161. - 60.

Parente, M.F., Gambaro, A., & Solana, G. (2005). Study of sensory properties of emollients used in cosmetics and their correlation with physicochemical backdrop. J Cosmet Sci., 56(iii), 175-182. - 61.

Pénzes, T., Csóka, I., & Eros, I. (2004). Rheological assay of the structural properties effecting the percutaneous assimilation and stability in pharmaceutical organogels. Rheological Acta, 43, 457-63. - 62.

Piana, Chiliad.L., Oddo, Fifty.P., Bentabol, A., Bruneau, E., Bogdanov, Southward., & Guyot Declerck, C. (2004). Sensory analysis applied to love: country of the fine art. Apidologie, 35, S26–S37. - 63.

Proksch, Eastward., & Lachapelle, J.M. (2005). The management of dry peel with topical emollients: recent perspectives. J. Dtsch. Dermatol. Ges., x(5), 768-774. - 64.

Roberts, K.P., Bames, H.A., & Carew, P. (2001). Modelling the flow behavior of very shear-thinning liquids. Chem. Eng. Sci., 56, 5617-5623. - 65.

Ross, C.F. (2009). Sensory science at the humane-machine interface. Trends in Food Scientific discipline & Engineering, twenty, 63-72. - 66.

Samavati, V., Emam-Djomeh, Z., Mohammadifar, M.A., Omid, M., & Mehdinia, A.50.I. (2011). Stability and rheology of dispersions containing polysaccharide, oleic acrid and whey protein isolate. Journal of Texture Studies, p. 1-14. - 67.

Savic, S., Lukic, G., Jaksic, I., Reichl, S., Tamburic, S., & Müller-Goymann, C. (2011). An alkyl polyglucoside-mixed emulsifier every bit stabilizer of emulsion systems: The influence of colloidal structure on emulsion skin hydration potential. Journal of Colloid and Interface Science, 358, 182-191. - 68.

Shewhart, W.A. (1980). Economic control of quality of manufactured product, American Lodge for Quality Control. - 69.

Spiclin, P, Homar, One thousand, Valant, A.Z., & Gasperlin, M. (2003). Sodium ascorbyl phosphate in topical microemulsions. International Journal of Pharmaceutics, 256, 65-73. - 70.

Stone, H.S., & Sidel, J.Fifty. (1992). Sensory evaluation practices. San Diego, CA: Academic Press. - 71.

Tadros, T. (2004). Application of rheology for assessment and prediction of the long-term physical stability of emulsions. Advances in Colloid and Interface Science, 108 – 109, 227–258. - 72.

Toro-Vazquez, J.F., Morales-Rueda, J., Ajay Mallia, Five., & Weiss, R.One thousand. (2010). Relationship betwixt molecular construction and thermo-mechanical properties of candelilla wax and amides derived from (R)-12-hydroxystearic acrid equally gelators of safflower oil. Food Biophysics, v, 193-202. - 73.

Tuarez, E.P., Sadtler, V., Marchal, P, Choplin, L., & Salager, J.L. (2011). Making apply of formulation-composition map to set highly concentrated emulsions with particular rheological properties. Ind. Eng. Chem. Res., 50, 2380-87. - 74.

Urban, 1000. C. C. (2004). Desenvolvimento de sistemas de liberação micro e nanoestruturados para administração cutânea do acetato de dexametasona. 2004. Dissertação (Mestrado em Ciências Farmacêuticas) - Faculdade de Ciências Farmacêuticas, Universidade Estadual Paulista Júlio de Mesquita Filho, Araraquara. - 75.

Vasiljevic, D., Parojcic, J., Primorac, M., & Vuleta, Thousand. (2006). An investigation into the characteristics and drug release properties of multiple West/O/W emulsion systems containing low concentration of lipophilic polymeric emulsifier. International journal of Pharmaceutics, 309, 171-177. - 76.

Welin-Berger, M., Neelissen, J.A.K., & Bergenstahl, B. (2001). The effect of rheological behavior of a topical anaesthetic formulation on the release and permeation rates of the active compound. European Journal of pharmaceutical Sciences, 13, 309-18. - 77.

Wortel, V.A.L., & Wiechers, J.Westward. (2000). Pare sensory operation of individual personal care ingredients and marketed personal care products. Food Qual. Pref., xi(ane-2), 121-127. - 78.

Zague, Five., Nishikawa, D.O., Silva, D.A., Babe, A.R., Behrens, J.H., Kaneko, T.One thousand., & Velasco, Grand.V.R. (2008). Influence of storage temperature on cooling intensity of topical emulsions containing encapsulated menthol. J. Sens. Stud., 23(1), 26-34. - 79.

Zenebon, O., Pascuet, N.S., & Tiglea, P. (2008). Métodos físico-químicos para análise de alimentos. Instituto Adolfo Lutz (São Paulo). On line version. Available at: http://www.crq4.org.br/sms/files/file/analisedealimentosial_2008.pdf

Submitted: March 16th, 2012 Reviewed: July 24th, 2012 Published: Dec 12th, 2012

© 2012 The Author(south). Licensee IntechOpen. This chapter is distributed under the terms of the Creative Commons Attribution 3.0 License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

How To Determine The Quality Of Makeup,

Source: https://www.intechopen.com/chapters/41063

Posted by: fleckthervin.blogspot.com

0 Response to "How To Determine The Quality Of Makeup"

Post a Comment